Thermal-fluid dynamic analysis CFD

Optimization of the energy performance of products and processes.

Effective answers to complex problems

Simulation based on Computational Fluid Dynamics (CFD), supported by appropriate theoretical knowledge, is a powerful tool capable of providing rapid answers and accurate results to designers, avoiding or minimizing the use of costly experimental tests.

Thermal-fluid dynamic optimization of products and processes can lead to significant benefits in terms of increased energy efficiency and performance.

CReAI deals with:

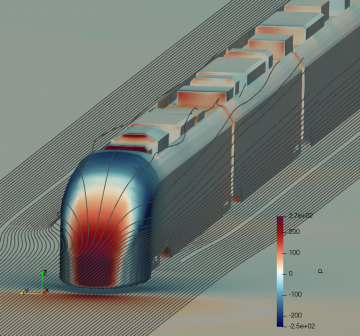

- Internal and external fluid dynamics

- Steady and transient analysis

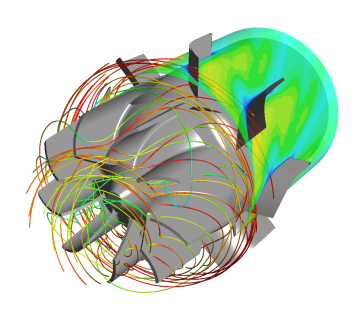

- Analysis and optimization of fluid machinery (fans, pumps, compressors, turbines)

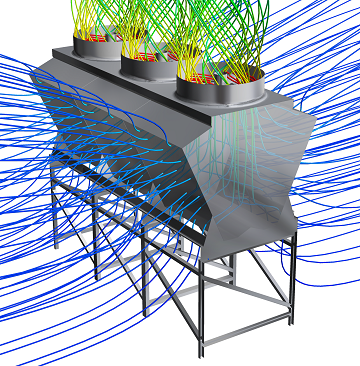

- HVAC systems

- thermal comfort estimation

- reduction of pressure losses

- optimization of air distribution

- estimation of CO2 concentration and of other contaminants that may reduce air quality

- Distribution systems for air or other fluids in industrial plants

- Optimization of existing machines

- Analysis and optimization of heat transfer

- Convection, conduction, radiation

- Solid/fluid conjugate heat transfer (CHT)

- Heat exchangers

- Filtration systems

- Cooling systems

- Cavitation

- Liquid and gas valves

- Multiphase flows

- Study of combustion problems and polluting emissions

- Simulation of fire scenarios

- Development of ad-hoc tools for design and analysis of industrial components through lumped parameters models or 1D/2D/3D modelling

- Research and development